| Chemical Name | CAS No. | In % By Weight |

| Butyl rubber | 9010-85-9 | 35.0% |

| Calcium | 7440-70-2 | 40.0% |

| Poly(ethylene) | 9002-88-44 | 10.0% |

| Polypropylene | 9003-07-0 | 10.0% |

| Resin | / | 5.0% |

Technical Advantages: Qingdao University of science and technology has always been leading in the research field of rubber and plastic technology, and it is also famous at home and even internationally. We have established a rubber composite product laboratory with our in-depth cooperation, and have a R & D team including Ph.D. personnel in polymer materials science. Through the continuous adjustment and application of the formula of rubber compounding agent to production, we gradually lead the domestic and international markets in the product performance and qualification rate of butyl sealant. At present, our customers and friends in North America, Japan and South Korea highly recognize our products and maintain a deep cooperative relationship.

Technical Advantages: Qingdao University of science and technology has always been leading in the research field of rubber and plastic technology, and it is also famous at home and even internationally. We have established a rubber composite product laboratory with our in-depth cooperation, and have a R & D team including Ph.D. personnel in polymer materials science. Through the continuous adjustment and application of the formula of rubber compounding agent to production, we gradually lead the domestic and international markets in the product performance and qualification rate of butyl sealant. At present, our customers and friends in North America, Japan and South Korea highly recognize our products and maintain a deep cooperative relationship.

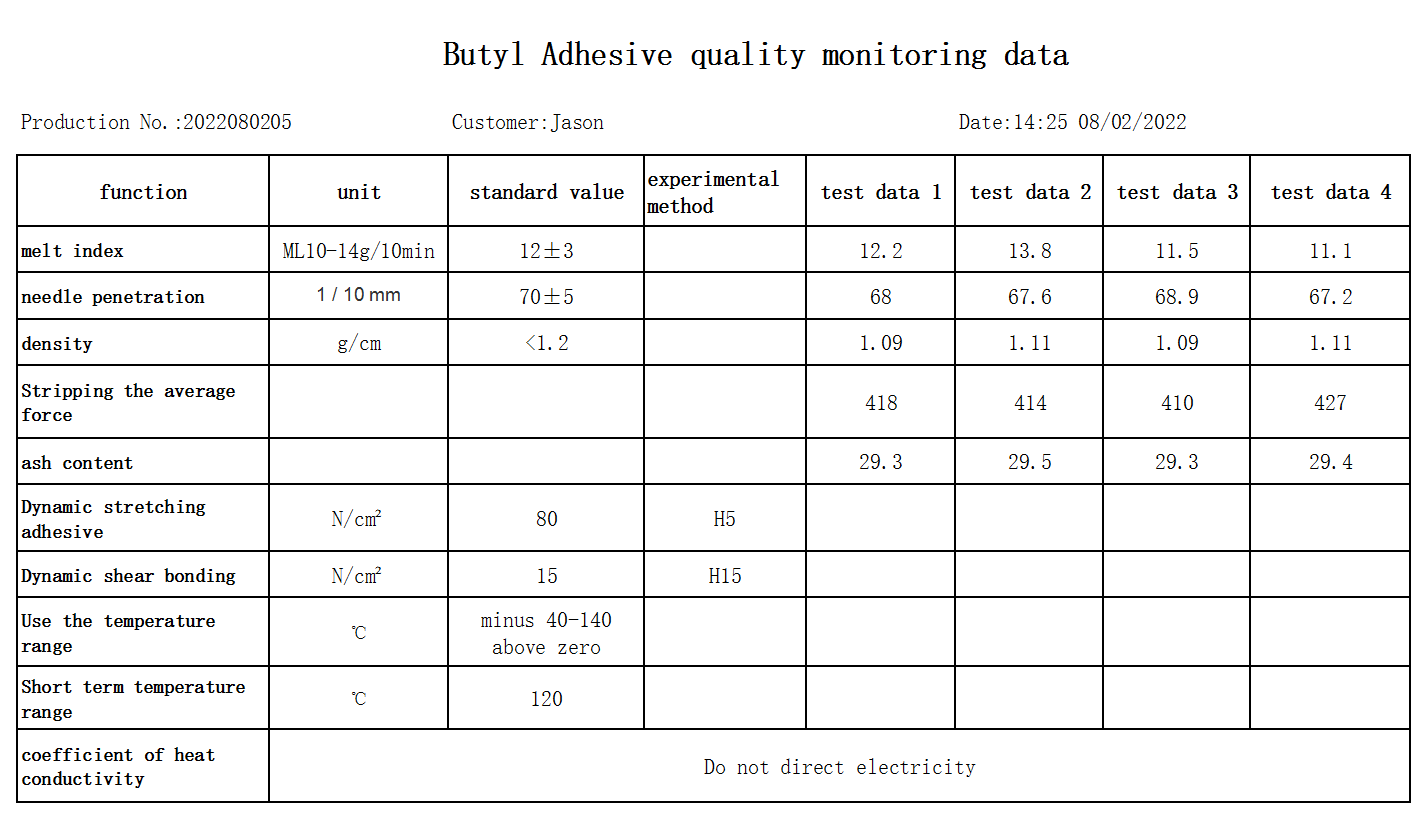

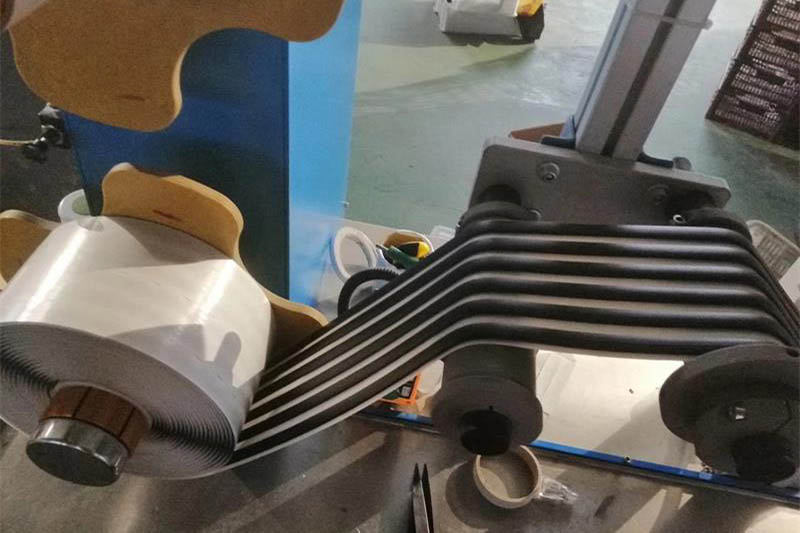

Customization advantage: relying on the professional technical team, we can customize products according to the different needs of customers. Color, shape, size, temperature and humidity of application environment, etc. When you put forward your demand scenarios and product requirements, we will adjust the product formula to meet your product requirements. (with what · up screenshot). Cost advantage: the company uses a large rubber mixer with high automation and production efficiency. There are 13 butyl rubber production lines, with a daily output of 60 tons and an annual output of more than 20000 tons. There are 15 coating production lines, with an annual butyl coating area of more than 30 million square meters, 2 double-sided butyl adhesive production lines, with an annual output of more than 8 million meters of butyl double-sided adhesive, and 1 lap tape production line, with an annual output of 3.6 million meters. The production scale determines the huge quantity of raw materials purchased in a single batch, so our raw material purchase cost and marginal cost of production are much lower than those of small and medium-sized factories. The corresponding products have strong price advantages. Quality control advantages: We have a specially built quality inspection laboratory, which conducts multiple spot checks on a single batch of finished products, and monitors the parameters such as tensile force, density, penetration, melt index, ash content, high temperature tolerance, etc., to ensure that the product performance parameters in the internal mixing process are consistent and stable. If a certain parameter is different from the standard value of the customized product, the production department will immediately adjust the formula of the mixing agent of the rubber mixer and conduct repeated sampling inspection so as to meet the performance standard required by the customer.Advantages of transportation trade: The finished products are packed by our own wrapping film and loaded. We cooperate with the transportation company of our own fleet, and the packaging, vehicles and personnel are within our control, ensuring the harmonious cooperation from packaging to loading to transportation, so as to avoid the transportation delay or even boarding delay caused by the covid-19 epidemic!

Customization advantage: relying on the professional technical team, we can customize products according to the different needs of customers. Color, shape, size, temperature and humidity of application environment, etc. When you put forward your demand scenarios and product requirements, we will adjust the product formula to meet your product requirements. (with what · up screenshot). Cost advantage: the company uses a large rubber mixer with high automation and production efficiency. There are 13 butyl rubber production lines, with a daily output of 60 tons and an annual output of more than 20000 tons. There are 15 coating production lines, with an annual butyl coating area of more than 30 million square meters, 2 double-sided butyl adhesive production lines, with an annual output of more than 8 million meters of butyl double-sided adhesive, and 1 lap tape production line, with an annual output of 3.6 million meters. The production scale determines the huge quantity of raw materials purchased in a single batch, so our raw material purchase cost and marginal cost of production are much lower than those of small and medium-sized factories. The corresponding products have strong price advantages. Quality control advantages: We have a specially built quality inspection laboratory, which conducts multiple spot checks on a single batch of finished products, and monitors the parameters such as tensile force, density, penetration, melt index, ash content, high temperature tolerance, etc., to ensure that the product performance parameters in the internal mixing process are consistent and stable. If a certain parameter is different from the standard value of the customized product, the production department will immediately adjust the formula of the mixing agent of the rubber mixer and conduct repeated sampling inspection so as to meet the performance standard required by the customer.Advantages of transportation trade: The finished products are packed by our own wrapping film and loaded. We cooperate with the transportation company of our own fleet, and the packaging, vehicles and personnel are within our control, ensuring the harmonious cooperation from packaging to loading to transportation, so as to avoid the transportation delay or even boarding delay caused by the covid-19 epidemic!

Application: Creep is the unique characteristic of butyl sealant. At the same time, it also has rubber properties and ductility. When it is pasted on the substrate, it will stick more and more firmly with the passage of time. Thanks to the particularity of butyl rubber molecular chain, butyl sealant can be applied to various substrates in theory, which is why it gradually replaces more and more waterproof sealing materials today. If you have requirements in other waterproof sealing fields, we look forward to exploring more application fields of butyl sealant with you.

Application: Creep is the unique characteristic of butyl sealant. At the same time, it also has rubber properties and ductility. When it is pasted on the substrate, it will stick more and more firmly with the passage of time. Thanks to the particularity of butyl rubber molecular chain, butyl sealant can be applied to various substrates in theory, which is why it gradually replaces more and more waterproof sealing materials today. If you have requirements in other waterproof sealing fields, we look forward to exploring more application fields of butyl sealant with you.